Registration is Open

Apply nowFunctional Materials and Additive Manufacturing

Master

Diploma awarded

: Diploma Expected in 2021Duration of studies

: 2 yearsCoordinator

: Khalil El MabroukIntroduction to additive manufacturing; Design adapted to additive manufacturing; Communication & culture EuroMed 1. Additive manufacturing by energy beam; Industrial manufacturing processes; Mechanics and aging of materials; Impact of the manufacturing process on the final mechanical properties; Numerical methods and techniques; Communication & culture EuroMed 2. "Additive manufacturing for the aeronautical and automotive industry" Additive manufacturing for the aeronautical and automotive industry; Industrialization of additive manufacturing; Metrology; Post-manufacturing treatment of parts; Numerical simulation of mechanical and physical properties; Innovation management and project management; Project Graduation. "Additive manufacturing for the medical sector" course Additive manufacturing for the medical field; Biomaterials and their applications; Metrology; Post-manufacturing treatment of parts; Numerical simulation of mechanical and physical properties; Innovation management and project management; Project Graduation.

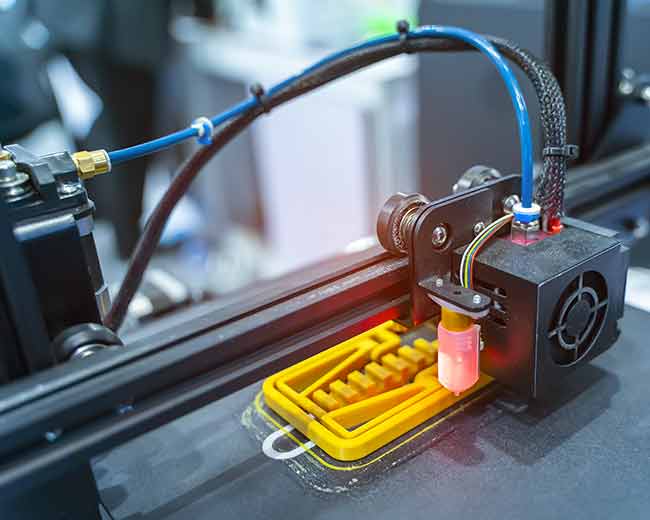

The Master “FUNCTIONAL MATERIALS AND ADDITIVE MANUFACTURING” is a multidisciplinary programme which aims to train students in both theoretical and applied approaches in the field of Additive Manufacturing. Through this Master, the student will gradually become familiar with the design of parts, the properties of materials, the choice of additive manufacturing techniques, post-manufacturing processes as well as the methods of characterizing the parts produced.

This multidisciplinary programme will allow the student to specialize in one of the following two streams, which are part of the key sectors of economic development in Morocco, namely:

Aeronautic and Automobile Industry

Medicine

Through this programme, the students will acquire a solid foundation in the field of materials. This training on polymeric, metallic and ceramic materials will cover the aspects of preparation, characterization and implementation in a context of use for additive manufacturing. The impact of the manufacturing process on the properties of the parts produced is also an important aspect which is covered during training.

Throughout the different semesters, the lessons will be backed by the UEMF scientific and didactic platform for the conduct of directed activities (TD) and practical work (TP). The Additive Manufacturing and Synthesis and Characterization platforms will thus allow students to carry out a large number of practical work on design, manufacturing and post-manufacturing aspects as well as characterization. A project approach will be used so that the student can, from a specifications manual that will be provided, design and produce a part that meets the formulated needs. These specifications may be established by the teaching staff of UEMF or by manufacturers wishing to assess the potential of additive manufacturing.

In addition to the technical courses, students will receive courses in Euro-Mediterranean communication and culture with the objectives of consolidating the mastery of multilingual skills and knowledge about the history and civilizations of the Euro-Mediterranean region.

Faculté Euromed de Génie (FEMG)

At the end of this programme in the field of additive manufacturing for the aeronautics, automotive and biomedical engineering sectors, the student will be able to perform the following tasks:

Evaluate the relevance of additive manufacturing compared to conventional manufacturing processes;

Translate the geometry of a part into additive manufacturing and / or machining operations;

Choose a manufacturing process for a given part according to quantifiable criteria;

Choose the optimal operating conditions (machines, forces, tools, etc.);

Perceive the contribution of IT tools for manufacturing;

Set the hypotheses for numerical modeling of manufacturing;

Communicate the needs to the technicians in a manufacturing workshop.

In addition, the use of application-oriented courses allows students to acquire the skills required for the proper operation of this manufacturing technique more quickly. The complementarity of knowledge between the different modules of this Master allows applicants to choose the appropriate path.

A scientific Bachelor’ degree or any diploma recognized as equivalent. Selection is based on the results and interview with members of an admission committee.

SLM - Metal energy beam additive manufacturing machine

SLS - Polymer additive energy beam manufacturing machine

Additive manufacturing machine using molten filament (FDM) and Stereolithography (SLA)

Additive manufacturing machine for ceramics

Mechanical design and digital simulation laboratory: 3D scanner

Polymer processing laboratory

Metallographic sample preparation equipment

Synthesis and characterization platform: Thermal characterization

Synthesis and characterization platform: Chemical characterization

Processing devices and rheology: Rheometer in the molten state

Mechanical characterization device

Rockwell hardness measuring devices and Vickers micro

Autoclave for the preparation of carbon fiber composites

Laboratory for shaping plastic materials (Electrophilization)

Thin film preparation laboratory

Heat treatment laboratory

Aeronautics and automotive industries already well established and growing strongly in Morocco

Medical field with the production of custom orthotics and prostheses

Pursue research activities